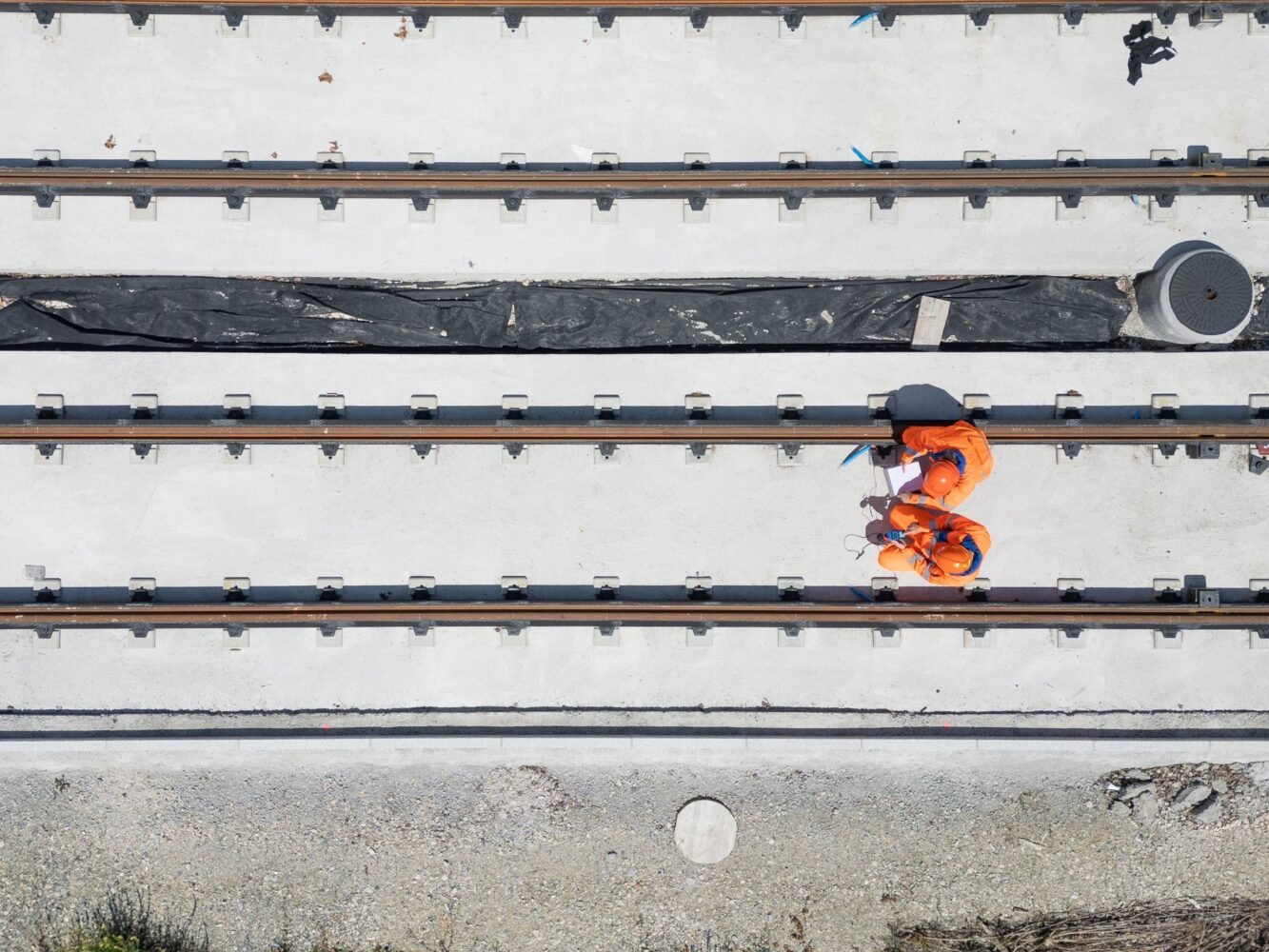

Safety concepts and risk analysis in rail technology

Enotrac relies on comprehensive safety concepts and risk analyses in rail operations. Our goal is to develop and evaluate safer rail systems. We use proven methods and standards such as FMEA and FMECA to analyse and assess risks. We also simulate crash scenarios to test the resilience of rail systems at train collisions and level crossings. Our solutions meet the highest safety standards and are individually adapted to the needs of our customers. We also offer support in the development of safety concepts for technical solutions in the rail sector, such as door control systems.

Methods and standards for risk analysis in rail technology

Risk analysis according to proven methods and standards

Safety in rail operations is of the utmost importance, and the application of proven methods and standards is central to safety. At Enotrac, we offer our customers and partners comprehensive support in the development and operation of rail systems. An essential part of our services is the implementation of risk analyses based on established methods and relevant standards.

EN 50126 and CSM-RA: Fundamentals for rail safety

In railway engineering, the EN 50126 and CSM-RA standards are of particular importance. They serve to achieve various safety objectives. These include obtaining the operating licence and type approval for new rolling stock, as well as checking existing vehicles for their suitability for use under special traffic conditions.

CSM-RA Regulation and the risk management process

The CSM-RA Regulation, also known as ‘Common Safety Methods – Risk Assessment’, was introduced to meet the requirements of the Interoperability Directive 2008/57/EC. This regulation requires the implementation of risk management for changes to subsystems of the rail system. It defines a structured and documented process that legally prescribes the identification of hazards, risk assessment, the definition of safety measures to control risk and the corresponding verification.

Updates and additions for safety

Over time, the legislation governing rail safety has been updated and expanded. Regulation (EC) No. 352/2009 has now been replaced and expanded by Implementing Regulation (EU) No. 402/2013 and Implementing Regulation (EU) No. 2015/1136. These updates and additions are crucial to continuously improving safety aspects in the rail sector.

DIN EN 50126: A key standard for railway safety

DIN EN 50126 is a central standard that, in conjunction with the parallel standards DIN EN 50128/DIN EN 50657 and DIN EN 50129, represents the specific adaptation of the basic safety standard DIN EN 61508 for the railway industry. According to the IRIS (International Railway Industry Standard) regulations, this standard is mandatory for all areas of railway engineering. This includes train control and signalling (signalling technology), rolling stock and fixed installations.

Comprehensive RAMS coverage

DIN EN 50126 deals with the determination and verification of reliability, availability, maintainability and safety (RAMS) for all railway applications and in all relevant life cycle phases. This standard is primarily intended for railway companies and railway suppliers, but its generally valid formulation also allows it to be applied outside the railway sector as part of a systematic RAMS/LCC specification and verification process.

DIN EN 50126: Part 1

Since its update in 2017, DIN EN 50126 consists of two parts. Part 1 defines terms, generic tasks in the RAMS life cycle and a systematic process for defining RAMS requirements. This part provides a clear guideline on how to identify and assess risks at different life cycle stages.

Part 2: Safety aspects of the RAMS life cycle

Part 2 of EN 50126 is dedicated to the safety-related aspects of the RAMS life cycle. It provides guidance and processes to ensure the safety of railway systems and to assess safety-critical risks. These standards are the foundation for ensuring safety in railway engineering and help to ensure that railway systems meet the highest safety standards.

Hazard identification workshops

Our hazard identification services are of paramount importance for ensuring safety in railway operations. We organise, prepare and facilitate hazard identification workshops, which are a crucial step in identifying and evaluating relevant risks in the railway domain.

Organisation and preparation

Organising and preparing hazard identification workshops requires an in-depth understanding of rail systems and their specific risks. We ensure that relevant experts and stakeholders participate in the workshops to provide a comprehensive picture of hazards. Participants are selected based on the specific requirements of the project and may include engineers, operations managers, safety experts and other professionals.

Moderation and implementation

During the workshops, we act as experienced moderators to guide the process and ensure that it is effective and focused. We encourage participants to openly discuss and collaborate to identify all possible hazards and risks. These workshops are interactive and require active participation from the participants to ensure a comprehensive analysis.

Creation and maintenance of the hazard record

After identifying and discussing hazards, we create a comprehensive hazard record. This record documents all identified hazards and the results of their assessment. It provides a clear overview of the identified risks and allows stakeholders to get an overview of the status of the safety analysis. This record is not only created, but also actively maintained to ensure that it is always up to date and meaningful.

Assess the identified hazards

Identifying hazards is only the first step. Risk assessment is particularly important for setting the priority of hazards and planning appropriate security measures. We assess the identified hazards by considering factors such as probability, impact and controls. These assessments serve as a basis for developing measures to reduce risk and optimise security.

System definition and interfaces

An important component of risk analysis is the establishment of the system definition, which includes the persons, devices and procedures involved. This also involves identifying the interfaces to other systems or processes. The security requirements specification is prepared in accordance with the CSM-RA and the CENELEC standards, whereby clear requirements are formulated.

Safety Analyses

Enotrac performs extensive safety analyses to verify and ensure that rail systems meet the highest reliability and safety standards. These analyses include various methods and techniques that are crucial in the field of risk analysis and safety assessment.

One of these methods is the Failure Modes and Effects Analysis (FMEA). This identifies and assesses potential failures by analysing their effects on the system, their probability of occurrence and the probability of their detection. This makes it possible to take steps to prevent or reduce failures and increase technical reliability.

The failure mode and effects analysis with criticality assessment (FMECA) is an extension of the FMEA that provides additional quantitative information on the criticality of failures. It takes into account the interactions of different failure causes and mechanisms. This enables a more in-depth analysis and identification of critical weaknesses in the system.

The Failure Modes and Effects Analysis with Diagnostics for Hardware (FMEDA) focuses on the hardware components of a system. It is used to determine the causes of failures and their effects in detail. Especially in the early phases of system development, FMEDA is extremely efficient in identifying and eliminating possible weak points at an early stage.

The fault tree analysis (FTA) uses Boolean algebra to determine the probability of a system failure. It analyses the logical links between subsystem failures that can lead to an overall failure. This method is used in industries such as aerospace and nuclear power engineering to ensure the safety and reliability of systems.

Finally, event tree analysis is also one of the safety analyses carried out by Enotrac. It looks at the sequence of events that can lead to a system failure. This helps to identify potential risks and weak points in the system and to take appropriate measures to minimise risk.

These safety analyses are of great importance to avoid safety-related failures and to verify compliance with safety standards. Enotrac uses these analyses in various industries and sectors to ensure the safety and quality of products and processes. Our experts understand the specific requirements and methods that apply in different industries and apply them in a targeted manner to achieve the highest standards and minimise risks.

Impact assessment

Our expertise extends to the application of specific standards for impact assessment in the event of train collisions and level crossing collisions. We perform crash simulations and compare the results with reference scenarios, taking into account the wagon strength according to EN 12663-1. This standard specifies minimum requirements for the strength of railcar bodies and forms the basis for their construction. The strength of the railcar is crucial for how well railcar bodies can withstand external loads, such as train collisions and level crossing collisions.

Safety concepts and architectures

Enotrac’s expertise in rail technology extends well beyond mere risk analysis. We understand the complexities and unique requirements of the sector and are committed to providing our clients with comprehensive support in developing and evaluating safety concepts and architectures for various technical solutions in the rail sector. One example of such solutions is door control and monitoring systems, which are crucial for the safety and smooth operation of trains and rail facilities.

In our work, we take the lead in coordinating interdisciplinary teams and ensure seamless collaboration between the various departments. We also work closely with external stakeholders, including independent assessors, to ensure that our safety concepts and architectures meet the highest standards.

Standards and regulations

Our approach is based on the applicable standards and regulations in the rail sector, which are essential for safety on rail systems. We use these standards as the basis for our work to ensure that our concepts and strategies meet the highest safety requirements.

Our comprehensive safety concepts and risk analyses are designed to ensure safety in railway operations and to minimise risks. Our main objective is to provide our customers with innovative solutions that not only meet the highest safety standards, but also ensure the efficiency and smooth operation of their railway systems.